¿Qué es la fabricación de metales industriales?

What is Industrial Metal Fabrication?

Industrial metal fabrication involves the integration of various parts or assemblies, usually made from sheets or plates, into industrial products. This process is critical in manufacturing large-scale industrial components and systems.

Key Industries Served

Aerospace

Industrial fabricators create components for aircraft and spacecraft, ensuring high precision and durability.

Alternative Energy

Fabrication in this sector includes parts for wind turbines, solar panel frames, and other renewable energy systems.

Material Handling

Fabricators produce equipment such as conveyors, cranes, and hoists used in material handling.

Pollution Engineering

Components for pollution control devices, such as scrubbers and filters, are fabricated to meet environmental standards.

Types of Products Created

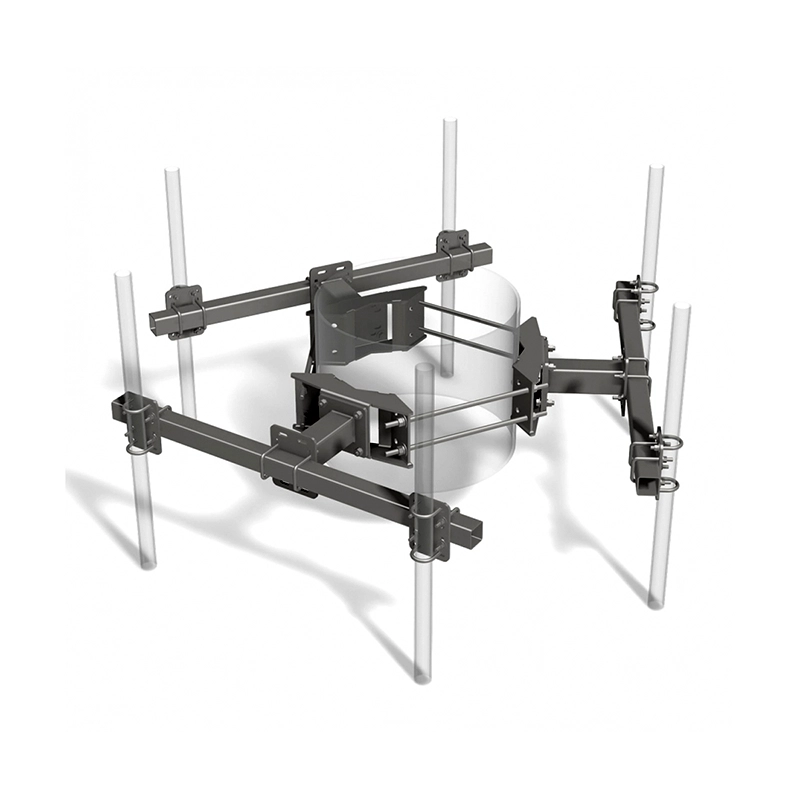

Tanks

Large tanks used for storage of liquids and gases are common products of industrial fabrication.

Silos

Fabricators create silos for storing bulk materials like grains, cement, and chemicals.

Heavy Machine Parts

Industrial fabrication involves producing parts for heavy machinery used in various industries.

Comparison with Structural Metal Fabrication

Complementary Parts

Unlike structural metal fabrication, where individual parts often stand alone, industrial metal parts are typically used as complements to each other in complex assemblies.

Integration Focus

The focus in industrial fabrication is on integrating multiple components into a cohesive system or product.

Common Materials Used

Sheet Metal

Sheet metal is widely used due to its versatility and ease of fabrication.

Plate Metal

Plate metal is preferred for its strength and durability in large-scale applications.

Tubing and Pipes

Tubing and pipes are essential for creating frameworks and channels for various industrial systems.

Bar Stock

Bar stock is used for manufacturing smaller components that require high precision.

Industrial Fabrication Processes

Cutting

Laser Cutting

Laser cutting is used for precise and clean cuts in sheet and plate metal.

Plasma Cutting

Plasma cutting is effective for thicker metals, providing fast and accurate cuts.

Bending

Press Brake Bending

Press brakes are used to bend sheet and plate metal into desired shapes and angles.

Roll Bending

Roll bending is used to create cylindrical shapes and large curves in metal sheets.

Assembling

Welding

Welding is a key process for joining metal parts together in industrial fabrication.

Bolting

Bolting is used for assembling parts that may need to be disassembled later.

Conclusion

Industrial metal fabrication is a complex and essential process for creating large-scale industrial components and systems. Serving a wide range of industries, from aerospace to pollution engineering, this fabrication type involves integrating various parts into cohesive products. The focus on integration and the use of diverse materials and processes distinguish industrial fabrication from other types of metal fabrication.